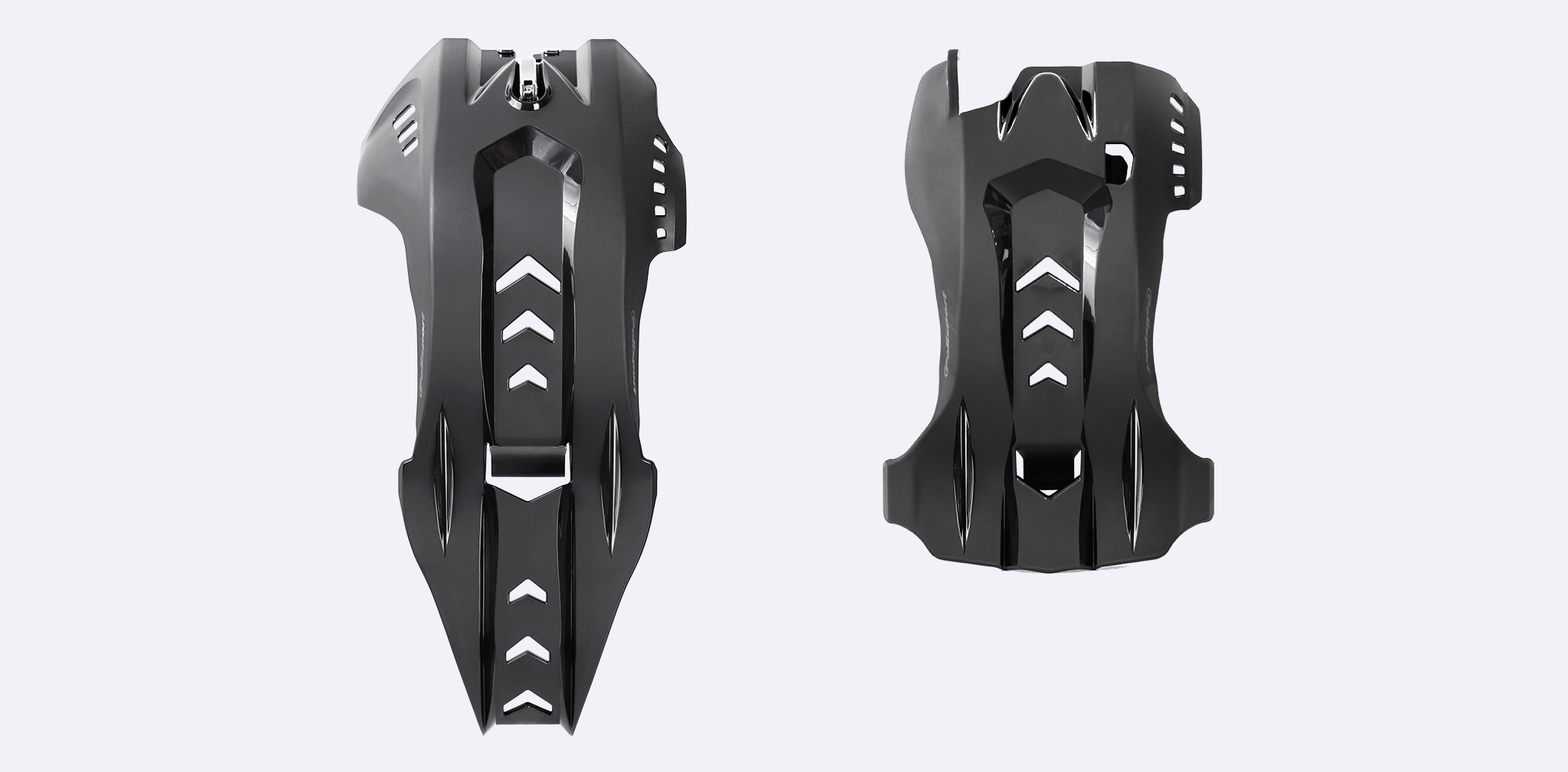

A disruptive skid plate designed for Polisport.

One of the recent partnerships between INNGAGE and Polisport resulted in a disruptive product. A new kind of skid plate that has been gaining prominence due to its fastening system.

The new Aegis protection, designed for cross and enduro riders, offers full coverage of the engine and chassis structure which provides safety, ease of handling and maintenance, and a robust fixation.

Aegis is part of the latest news in the Polisport catalogue and its growing demand has already triggered the adaptation to other motorcycle brands/models.

Nuno Pires, industrial designer at INNGAGE, gives us his perspective on the design process for this product.

1.What was the problem/challenge launched by Polisport?

Nuno Pires: When Polisport contacted us, they aimed to take the next step in the range of frame protectors for motocross and enduro contexts.

We are talking about off-road motorbikes that without protection would be damaged, jeopardizing the performance of the bike as well as the safety of the pilot. The challenge was to develop a solution that would protect not only the lower part of the bike but also the linkage area from impact and projection of debris. At the same time offering a protection area superior to traditional solutions on the market. We also had to take into account other factors such as stability, assembly, robustness, ventilation and a style that remained consistent between the different motorcycle models. After the motorcycle protection was guaranteed, these factors are highly relevant as they add value and differentiate the product on the market.

2. How did you approach the problem? Any specific strategy you want to share?

NP: On average, a pilot does the maintenance and cleaning of his motorcycle at least once a week and it is a process that involves manoeuvring tools, changing oils, disassembling and reassembling the protection. So, we knew that the two important points to take into account would be the covering of the area to be protected on the bike and the comfort in the ease of assembly.

At this stage, it was important to understand deeply the target audience. The proximity that Polisport has with its customers allowed us to acquire valuable insights that quickly became opportunities. The enduro/motocross context is very particular and challenging.

When our team visited Polisport’s headquarters, I remember noticing the level of abrasion that a motorcycle is subjected to in this type of races. We are talking about dented exhausts, footpegs worn out due to friction, damaged frames with cuts or scrapes and deep hammering that just barely pierce some of the bike’s components. We understood the importance of a protection part to be as adjustable as possible to the motorcycle.

These “scars of war”, which we can see in the photograph, facilitated our work, as it was easier to understand which areas needed to be urgently protected. The strategy was precisely this, to understand the intensity that these motocross and enduro contexts offer, and to understand how protection parts can improve the rider’s experience both during the race and in the post-race.

Seeking for credibility is what moves us throughout the design process. Not involving those who in the future will be connected to the product and will use it, is to create a product for a non-existent audience.

3. What was the key concept for product development?

NP: After speaking with some riders it became clear that an external tool to assemble and dismantle the protection was a problem. Riders do not want to carry unnecessary tools, they want to compete.

When it comes to maintenance, the problem riders point out is: “It’s good to feel that the bike is protected, but on the other hand, I feel that this amount of screws, tools and hardware only makes me lose more time cleaning, assembling and disassembling”.

Therefore, the main focus was on significantly improving the experience of these users and for that, it was necessary to define some directions. First, we went through reducing the number of the necessary hardware, moving from 4/6 screws and 2 fasteners (like most solutions on the market) to 1 screw and 1 fastener, in order to shorten maintenance time of the motorcycle. On top of this, our design pointed for a screw that comes in the form of a quick-release, a solution already known in the bicycle market that can be used without tools.

Another equally important aspect detected in the market by Polisport was an increasing desire to protect the linkage of motorcycles, allowing the possibility of choosing a product with or without an extension for this purpose.

In terms of design language, this type of product has to offer robustness and resistance and this led us to work on a more aggressive design with sharp angles and bulky shapes. This look and feel of protection and safety increase users’ confidence in the product, and consequently in the brand, and allows riders to evolve their performance without fear.

4. What kind of relationship did you establish with the client during the project?

NP: Our relationship with Polisport is fantastic. Their development team is really dedicated and professional. The development of this project required access to specific KTM and Husqvarna bikes and Polisport has always provided us with the necessary tools.

The good communication between the two teams proved to be essential to maintain the dialogue active, crucial for the project. Each new input that emerged was discussed between us and the Polisport team and together we defined solutions and directions to follow.

In the latest prototype tests, both teams participated actively to identify the greatest number of improvements to ensure that the protection offered the best possible experience for the pilots.

5. How does the product strategy differ from the competitors?

NP: We are talking about the first skid plate cover on the market with a quick-release system. This system enables a quick and intuitive assembly and disassembly of the protection part, which for a rider can mean winning or losing a race.

The extension to the linkage is also a plus since we are able to prevent interference in its performance, avoiding resistance in more muddy terrains.

In short, if we can solve the main problems we see in products sold on the market, if we prevent the protection parts from being a blockage in application and maintenance, and if we can still make the rider feel extra protected, then we have accomplished our mission and we have a differentiating product.

6. What and how do the phases of the whole process work?

NP: As soon as we received the briefing, the first phase was focused on the consumer. From the first impressions, we realized that a product that should be discreet and functional was a big problem to motorcyclists. So we collected some feedbacks, analyzed behaviours, habits and priorities, and turned those concerns into opportunities.

We also looked at the solutions the market has to offer. We collected some inputs from the competitors and understood what the consumers’ priority points were. This analysis also allowed us to detect which are the strengths and weaknesses of the competitors in order to create some distinction in the product.

After defining the characteristics the product would have, we addressed more technical issues such as fixing the protection to the frame, the integration of the quick-release fastener in the part, the extension to the linkage, etc. These points were validated from a very early stage with simple and basic prototypes, which fulfilled their function. We also identified the areas that are most exposed and which need a larger protection area. And of course, in the end, culminating in a design that suited the context, with a geometry that allowed a smooth industrialization.

None of this followed a linear sequence. Going back and forward is part of the job, constantly updating the design until the moment of the first SLA prototype for motorcycle testing. Then it was all about testing and refining. From CAD to motorcycle and from motorcycle to CAD. Several times, until we guarantee a perfect harmony between product and requirements.

7. What were the biggest difficulties in this project?

NP: I would rather say challenges instead of difficulties, and I will undoubtedly choose 3D modelling. Being able to combine the rigour of the adjustment that was required for this product with the 3D digitization of the bike was challenging. As we know there are irregularities in surfaces on 3D scans of this nature. These irregularities together with the complexity of the model’s surfaces brought some difficulties to the CAD modelling, where the smallest change implied formal complications. From then on, other protections were developed, this time using a faster process and with fewer obstacles.

8. As a designer, do you see yourself in this collaborative process between the design team, client team and users?

NP: Seeking for credibility is what moves us throughout the design process. Not involving those who in the future will be connected to the product and will use it, is to create a product for a non-existent audience.